|

Retrocomputing is always a lot of fun. Machines which you can fully

understand and fully control are exceedingly rare in these days of

complex computing. When you sat down to a machine like a Commodore 64

or an Apple II, you were certainly the one in charge.

Some machines take this a little farther. These machines, which

we colloquially call “blinking light machines” let you peer into their

operations a little more deeply. For example, I have an Altair 8800

clone as well as the PiDP-8 and PiDP-11 kits. All of these machines

have lights which allow you to see the memory and data buses of the

processor along with varying amounts of information about their CPU’s

internal state. Even better, these machines have a bank of switches

which allow the programmer to directly put a binary machine code

program in memory. These machines operate without even the slightest

pretense of abstraction, and they also make delightful blinking

patterns.

The thing of it is, all of my blinking light machines up until now

have been illusions. My Altair is based on a microcontroller which

emulates a fully loaded machine (about $16,000 worth of hardware in

1975 dollars, or $64,000 when adjusted for inflation!) The PiDP kits

are based on simh running on a raspberry pi. These machines all

provide a good emulation of the original experience, but the hardware

interactions are still an illusion. That is why I was so excited to

learn about another blinking light computer kit, Lee Hart’s

1802 Membership Card.

This machine is a reproduction of the COSMAC ELF machine that was

introduced as a DIY computer in a 1976 issue of Popular Electronics.

I had been vaguely aware of the ELF, but never really gave it much

thought. It was a sort of footnote in my knowledge of microcomputing

history. So I read a little bit of the 1976 article and I read the

membership card website and came to the conclusion that I just had to

build this little blinking light machine. Even better, this is no

simulation, it is a real 1802 processor surrounded by period correct

parts!

I put in an order via the sunrise-ev

website. Like many hobby kits, it is sold via simple PayPal invoicing.

As I was ordering two things, the full membership card kit and a ROM

chip, I used an email-based order form so that it would have correct

shipping. I received a PayPal invoice within 24 hours of emailing Mr.

Hart, and then I received the kit approximately seven days later.

After I sent in the payment, I printed out the membership card manual

and spent some time studying up on the construction process as well as

the front panel operations.

When the kit arrived, I was pleasantly surprised to see that it

included a color printed manual. I knew that it included a manual,

I was just not expecting such a nicely printed copy! Also, note that

it arrived with 3 holes already punched for easy binder installation.

It also reads like a hobbyist manual from the era, so it is a real

delight to work with.

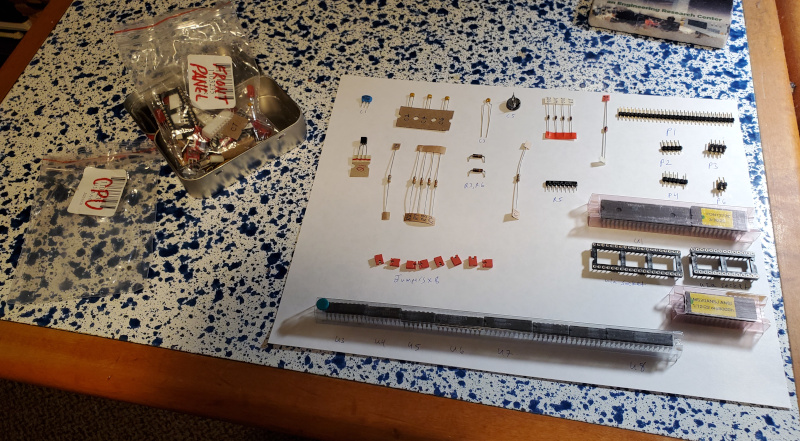

The manual explains that “this is an adventure, by cracky!” a clear

callback to the Captain Cozmo’s Whizbang book which is linked from the

manual’s pdf. The membership card is our gateway into the world of

microcomputing, and the first step of the journey is to pass an

aptitude test. We are to unpack and catalog each of the parts, and

prepare for assembly. The manual gives us a handy form to do this,

checking off each component as we go. The kit was shipped with its

components inside of the Altoids tin which will ultimately serve as

the machine’s case. There are two small baggies inside which were

labeled “CPU” and “Front Panel.” I began construction last Thursday

evening and decided I would build the CPU board on Thursday and the

front panel on Friday.

I believe I passed the aptitude test. As I took inventory of the CPU

parts, I did what I typically do with a kit. I placed the parts on

a piece of paper and labeled them. Apparently, Lee thinks

the same way. (I feel that after the informal tone of the manual,

I can call him by his first name. He can certainly call me “Bob”

should we ever meet.) Also, he has thoroughly designed his board and

labeled every component with a letter and a number. A nice

professional touch that not all kits follow! Even better, the

components that were on tape strips arrived already labeled. This last

bit is why I think Lee and I are on the same wavelength. I would have

done this as I found each part. This makes the kit somewhat friendly

to beginning level builders, though I would not recommend the

membership card to someone new to soldering!

I fired up my trusty low-cost digitally controlled soldering iron and

dialed it into 290 degrees Celsius. I am using 63/37 solder, with all

of its luxurious lead. Lead-free solder is definitely the wrong

choice for this board as the pads are close and small, and so reliable flow is

a must! Those in the know will note that I set my iron to about 100

degrees above 63/37’s typical melting point. I do this because this is

a very fine tipped soldering iron and if I set it right at the melting

point heat transmission takes a bit too long. I prefer to flow quickly

and reliably, and this is about the point where I can do that with

this tip.

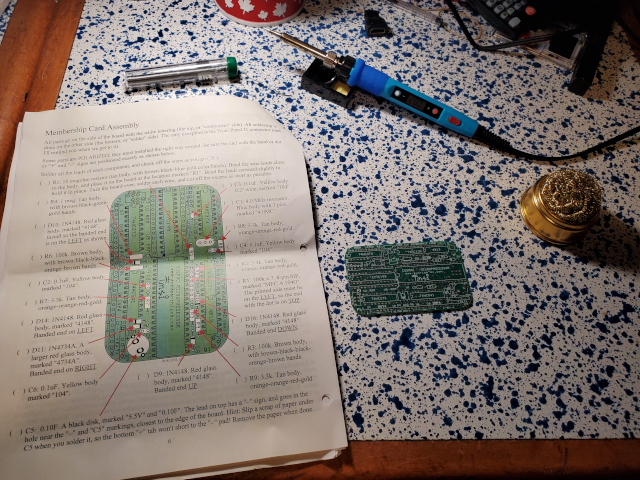

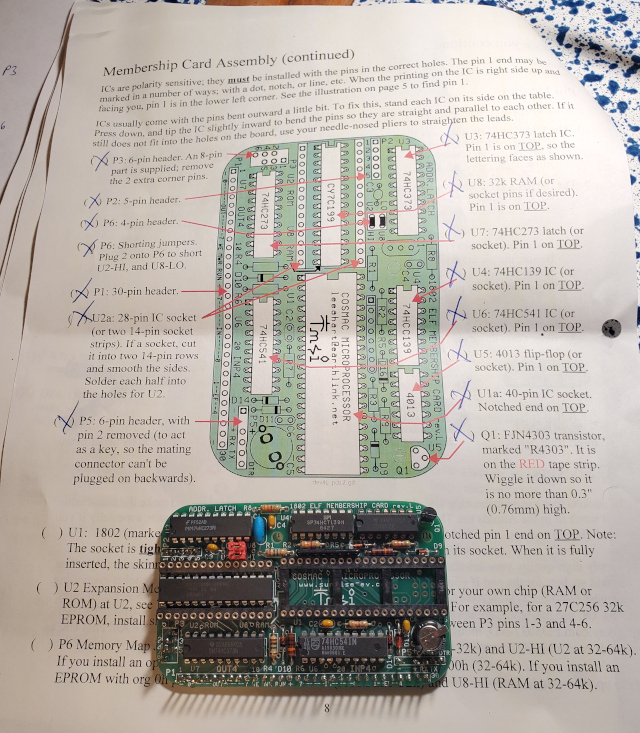

Did I mention before that this manual is a pure delight? Well, it

bares repeating! I love that on a single page we get a check list that

also shows us where to put everything. Most of the positions on the

board are screen printed, but sometimes close components make

identifying the correct holes difficult. Having this

picture clears up the confusion. Working slowly and methodically,

I had no trouble finding the correct position of each component.

I decided to build the board up according to the hight of the

components. I did the diodes (all denoted as D followed by a number),

then the resistors (R), and finally the capacitors and crystal (C).

I had trouble

finding the right bend spot for the leads on a couple of diodes, but

I generally found the hole spacing easy to work with and wound up with

a relatively neatly aligned board.

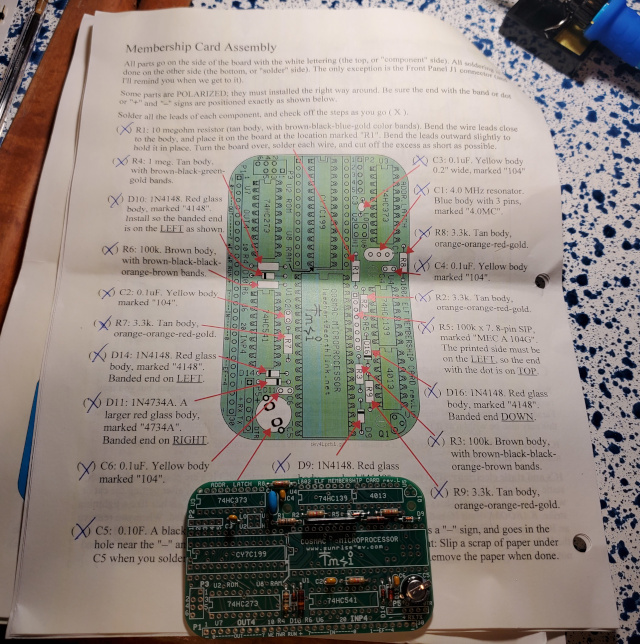

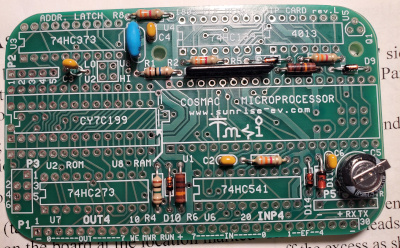

The construction of the CPU board is done in two main parts. The first

was to put all the discrete components in place. This is what was on

this page, and here is a closeup of the board after that page.

You can also see the fine work done in the PCB. It is well designed

and period correct. There is no fiddly surface mounting to be done. It

is all through hole components on a dual sided PCB. There is no reason

this board could not be built in the late 70s or early 80s.

One thing I dig about this design is the super capacitor in the

lower right hand side. This is used to drive the RAM after power is

removed, thus the membership card will retain its contents when it is

powered off. The CPU will lose state, but loaded programs will remain

for quite a while after power down. This was also sort of a feature of

the original ELF, with several hobbyist adding RAM backup batteries so

they did not have to re toggle their machine code all the time. This

is a really nice feature for microcomputers of the era.

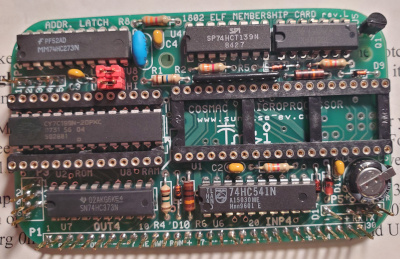

Ok, on to the second part of CPU construction! I elected to take care

of the sockets and headers first and then solder the ICs that are

directly attached to the board in place.

Ok, on to the second part of CPU construction! I elected to take care

of the sockets and headers first and then solder the ICs that are

directly attached to the board in place.

The headers are probably the most difficult part of everything. The

instructions outline an easy way and a hard way. The easy way is to

drop the pins in place and then solder them from the back of the card.

You should only do this if you are not building the front panel card

though! It mentions that you can do this unless you want to fit both

boards in the Altoids tin, but the headers and stand offs used to

assemble the two boards into one unit only have clearance enough for

the hard way. The hard way is to push the plastic strip down on the

pins and then install them from underneath. You solder them on to the

top of the board and then cut off the plastic strips and cut the pins

flush with the bottom of the board.

Because I am building both boards, I elected to do the hard way.

It was not all that difficult, but probably one of the harder parts of

the kit to construct.

Another thing that gave me a bit of trouble can be seen on the left of

the board. In order to save space, the optional ROM chip straddles

a rather narrow 32K RAM chip. In order to accomplish this, the

instructions have you cut apart the ROM’s socket. When I did this, and

smoothed out the contacts, it made the socket a little harder to keep

aligned while soldering. I held it in place with masking tape, but

it managed to travel a bit upwards which makes my ROM chip sit

a little too high, thus negating all my careful work with the header

pins! If I had it to do over, I would have first soldered the ROM

socket in place, and then clipped the plastic once it was on the

board. So if you build one, you should do that.

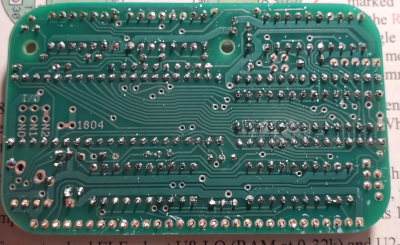

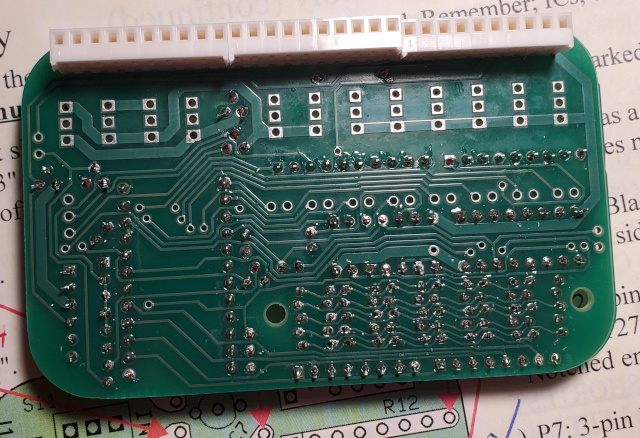

Here, you can see the back of the board after all of the soldering.

Note that this is close work. Be careful of dry joints and cold

joints! Desoldering on this would be a bit difficult, so take your

time and do things correctly the first time. Nevertheless, I found it

to be reasonably easy to work with. I had no burnt areas, though I do

have a bit of flux to clean up. Also, note that the bottom of the

board is where the headers are. They look rough, but remember they are

soldered on the component side of the board. They look rough because

I have been at them with a pair of side cutters! You can see the other

headers on the board have the same treatment.

After a little bit of fiddling with the chips, I have them installed

in their sockets and the CPU board is complete! We see the ROM on the

left and the CPU is on the right. The RAM cannot be seen because it is

beneath the ROM chip.

A word of advice

on the socket front. If you work with ICs, an

IC

Pin Straightener too is a must-have.

ICs have pins bent out slightly when they ship, and these things will

move them into a right angle which are perfect for inserting through

holes and into sockets. Oh, and don’t get these from places like eBay

or Mouser. I’ve seen them go for $75.00. You can get them much more

cheaply. Don’t give more than $10.00 for a pin straightener!

So with the CPU board completed, I turned in for the night. Friday

I taught two of my favorite classes (a theory of computation course

and an operating system course) but I spent most of the day dreaming

of the things I would do with my 1802. After all, I have never

programmed an 1802 and I was excited to meet my new friend!

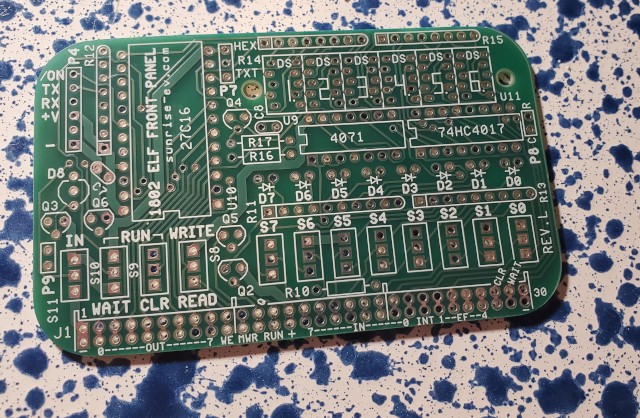

The front panel instructions were pretty much like the CPU

instructions. First, I inventoried the parts and then set to work. One

thing to notice about this board is the 7-segment display ports. The

original version of the kit had six displays which printed out ASCII

text. This revision only comes with two displays which automatically

renders the contents of the output port in hexadecimal on digits three

and four. There is a jumper which allows you to select which set of

characters will be generated by the ROM which drives the displays.

When I ordered the kit, I knew about this because I had read the

manual. I decided that I also wanted those additional displays so

I could play with the ASCII option. I have this vision of taking this

to my assembly and organization class next semester and toggling in

a “hello world” program which then displays on the front panel.

To pull this off, I double checked the schematics in the manual and

saw that these display units share a common conductor across the pins

and then are activated via latching the common ground. This meant that

if I simply purchased the additional components, I should be able to

have all six displays. So that is just what I did. These displays are

readily available at Mouser Electronics (

Part

Number 696-LDS-A3506RD.) I ordered four of these the same day I ordered

my 1802 membership card. They arrived the day before the kit, and so

I included them in my build.

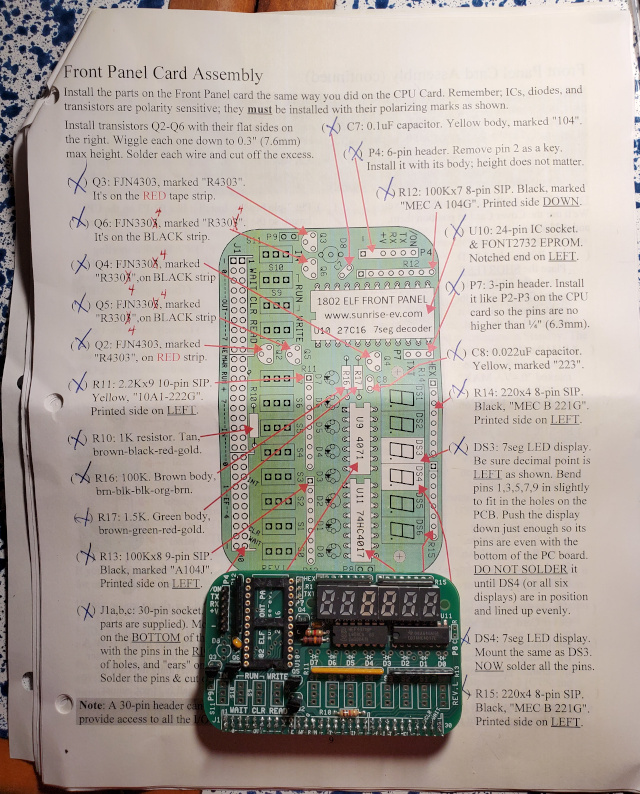

The first step in building the front panel is to put all of the

discrete components and sockets in place. Again, I worked my way up in

order of height. One of the trickiest parts of this section are the

displays. Rather than have the holes in a straight line, they are in

a sort of zig-zag pattern, probably due to sizing constraints. The

instructions tell you which pins to bend to get them through the

holes, and if you follow those it is reasonably easy. Also, I noticed

that there was a slight mismatch between the backgrounds of my

displays and the ones that came with the kit. So I put the two that

came with the kit in positions 3 and 4 (these are the digits you are

supposed to have), and then the other four surround them. You can see

that color difference in the photo, even though I did use the

specified part number. I suppose there is some variation between lots

or something.

In addition to the socket for the display driver, there is a line of

connectors on the bottom used to mate the front panel with the CPU

board. There is an optional row of headers that can be added at the

bottom, and I supplied the header strip for that from my own stock of

parts. For these and the jumper pins, I once again used the “hard

method” of assembly because they have to clear the back of the front

panel’s cover board. The pins on the left are mounted in the usual way

with the plastic strip on the component board. These are the serial

port and power connections, which need to be accessible when the cover

is on.

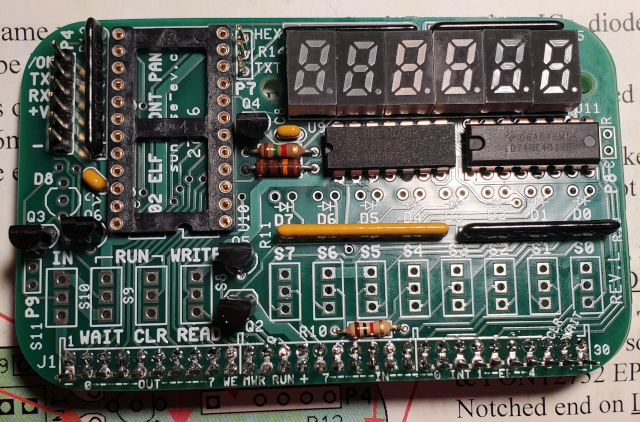

The ICs on this board serve to latch the display as well as provide

input from the switches. You can see the connection points for the

switches and push button on the board, and the next step is to add

those components in.

As I put this together, I renewed a bit confusion that I had about

what the front panel operations would be like for this system. With

only 8 lights, it must be the case that it visualizes the data bus.

This turned out to be incorrect. These lights are plugged into an

output port of the 1802. A cursory bit of reading in the information

from Popular Electronics seems to suggest that the 1802 provides some

front panel operations itself. I am not sure if this is the case but

I will investigate further later. I looked in the manual and realized

that there would be no visualization of the address bus, and that both

the switches and lights should be under fairly easy program control.

This is different from other blinking light systems I have used, so

I am intrigued!

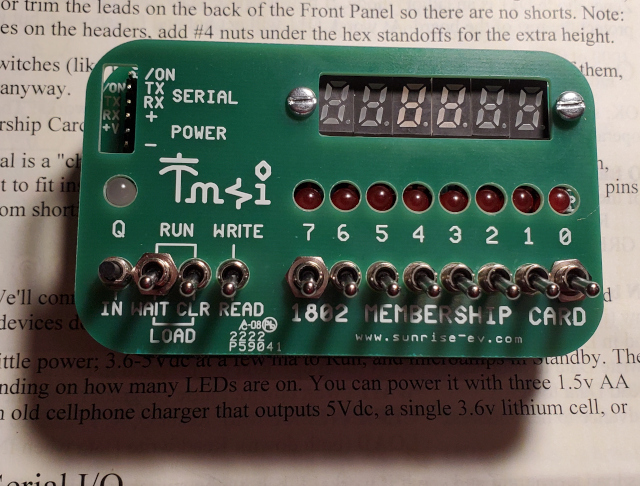

The front panel is finished by adding the lights and switches. The

front panel cover acts a sort of jig so you can align the switches and

lights and get everything at the right height. This made soldering the

switches and lights very easy. The instructions have you put the

halves together and then fasten them lightly with the screws beside

the display. I did this, but I neglected to put the spacers in place.

This meant my switches were fine but my lights were a little too short

as they were pushed into the board. When the cover is in place with

the spacers, they do not quite poke out, but they are plenty visible.

Oh well, these little variations are what make each membership card

special!

The final assembly step is to put the the two boards together. Here,

I discovered that my problem with the ROM IC meant that the two parts

won’t mount evenly. But with a little bit of light pressure on the

screws I was able to get them to go together a bit. I think I will

have to redo the ROM socket.

When I powered it on, it lit up! At first I was a bit disappointed.

After all, building a kit is fun but debugging a kit should always be

a part of the experience. I tried to insert some data into memory.

I reset the 1802, and I put the number zero in. I saw “00” on the hex

display, and no lights were on. In the next byte, I set my switches to

put in a one, and I saw “01” on the hex display and “00000001” on the

lights. So far so good! Then I put in two on the switches, and I saw

no lights and “00”. Uh oh….

A little more testing revealed that only the bit 0 switch appears to

be working on the data input. I can insert a 0, or I can insert

a 1.Those are my only two bytes. Oh joy! I get to debug things!

But that is where I will leave off for now. I put the kit together and

my evenings this week will be spent in debugging the boards and in

exploring the 1802 architecture.

So check out my next post for my first round of debugging. As always,

thanks for reading!

The story continues in 1802 Membership Card Debugging – Part 1

Computers

|

Home

|

Humor

|

Links Computers

|

Home

|

Humor

|

Links

|